Steam flaking mill solutions

Steam corn flakes are made by steam heat treatment to ripen and soften corn, and then processed into 1.5mm-2mm flakes using a corn flake press. The principle of steam corn flakes is actually a gelatinization process, which is to break the hydrogen bonds of tightly bound corn starch through gelatinization, thereby improving the digestibility of corn starch by animals.

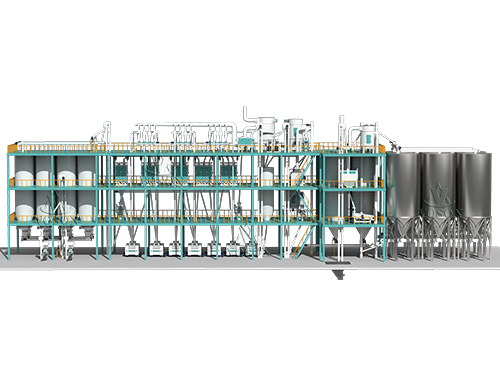

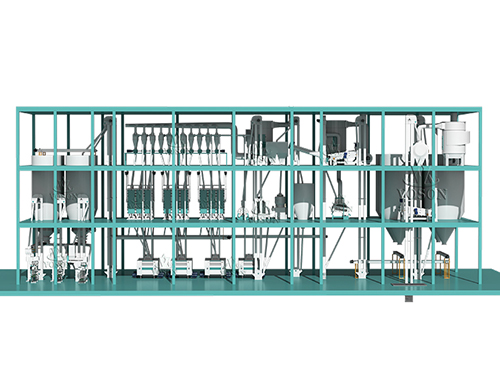

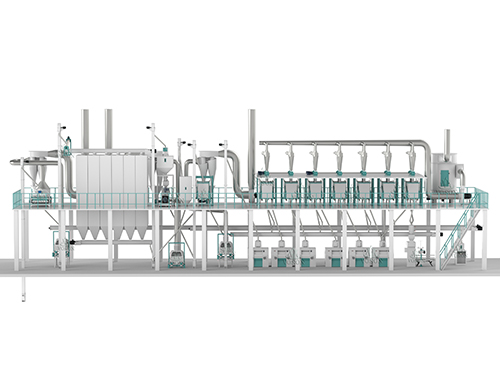

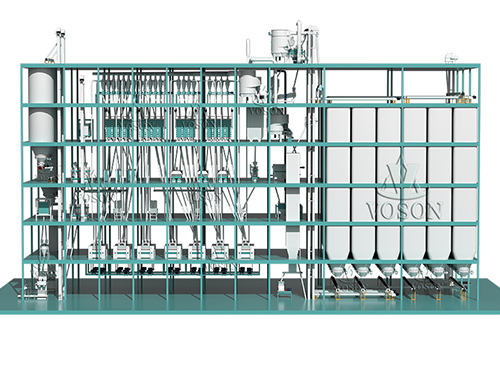

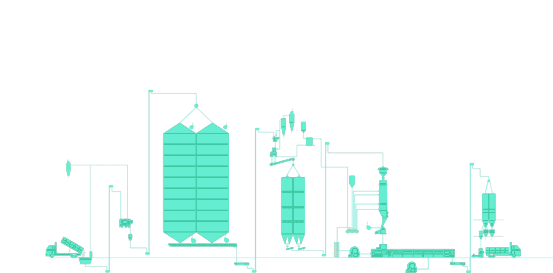

Main production process: warehouse entrance → primary screening → steel plate warehouse → cleaning → soaking warehouse → conditioning tower (cooking) → tableting → drying box → finished product warehouse → packaging scale/bulk

We also supply 10-20T/D Wheat Flour Machine, 100-300T Wheat Flour Mill Plant, 20-30T/D Maize Flour Milling Machine

You can contact directly, our engineers will answer your questions about process and best price. Get a Free Quote

Overview of Steam flaking mill Line

Below is the parameters of one of our options, feel free to contact for more details if you are interested in our product!

| Model | Capacity(T/24h) | Power(kw) | Outside dimensions(mm) | Weight(T) |

| VSYP60*80 | 40-50 | 11*2+0.55 | 1800×1500×1800 | 1.5 |

| VSYP60*100 | 50-60 | 18.5*2+0.55 | 1900×1400×1500 | 2 |

| VSYP60*125 | 80-100 | 22*2+0.55 | 2500×1978×2308 | 4 |

| VSYP80*100 | 120-150 | 55*2+0.75 | 2150×2000×2210 | 6 |

| VSYP80*125 | 180-200 | 55*2+0.75 | 2400×1800×1810 | 6 |

Our engineers have a lot of experience, they can design different solutions according to actual needs to ensure that the most suitable one is provided for customers. When you consult, our technicians will confirm your raw materials and requirements. See more details below, and you are also welcomed to customize your Steam flaking mill now: Get it for Free

Features of Voson Steam flaking Mill Line

We develop complete solutions for maize flaking Mill、Oatmeal flakes Mill、soybean flakes Mill and so on- from traditional wheat flour mills to combined mills for whole wheat and atta flour. Years of equipment research make our milling equipment a significant market advantage:

Zero steam overflow:

1. Good sealing effect and longer life;

2. The main equipment is equipped with a steam recovery device, and the moisture absorption fan discharges the steam to the outside;

3. Avoid corrosion of equipment in the workshop;

Compact and elaborate design:

Compact and elaborate design ensure Low investment and low power consumption and running costs.

High quality of grain flakes:

1. Low powder content

2. Maturity

3. Anti-mold and agglomeration

Types of materials can be processed