The drum primary cleaning machine is usually used in the raw material processing stage of the grinding equipment. Specifically, it is installed in the initial cleaning process of the raw materials. Its main function is to remove large impurities, straw, ropes and other debris that are not suitable for entering the grinding system to ensure the safe operation of subsequent equipment and improve the efficiency of grinding. Therefore, it is usually located at the front end of the grinding equipment for the initial screening and cleaning of raw materials.

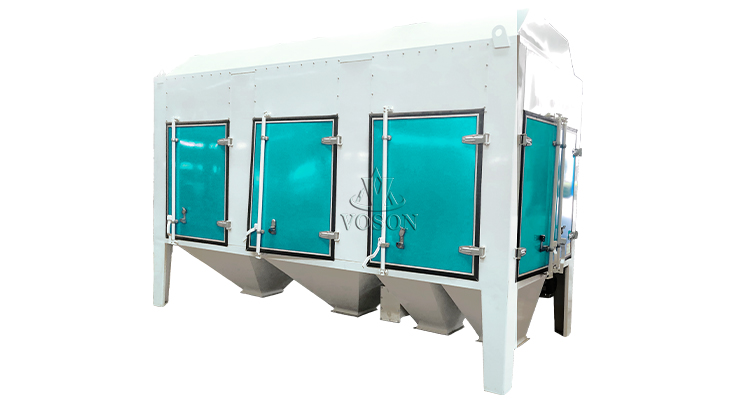

TSCY Series Single Layer Cylinder Primary Cleaning Screen Machine Features

1、A suction outlet is reserved on the top of the machine, which is more hygienic and clean;

2、Unique sealing door, effectively prevent dust from rising, beautiful and convenient;

3、Reinforced optimized design, strong, strong, stable, and explosion-proof configuration;

4、Fixed, mobile, and air-selected combined for users to choose

5、The screen cylinder angle can be adjusted, this can be used for adjusting the output capacity and cleaning effect.

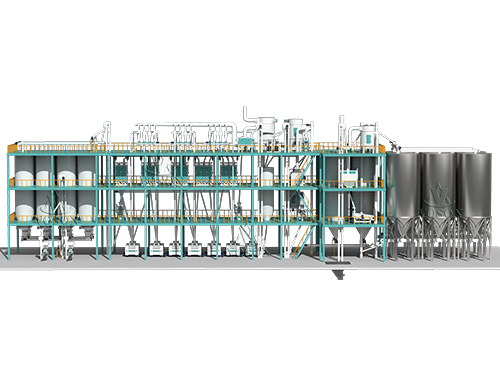

Maize Flour Processing Steps

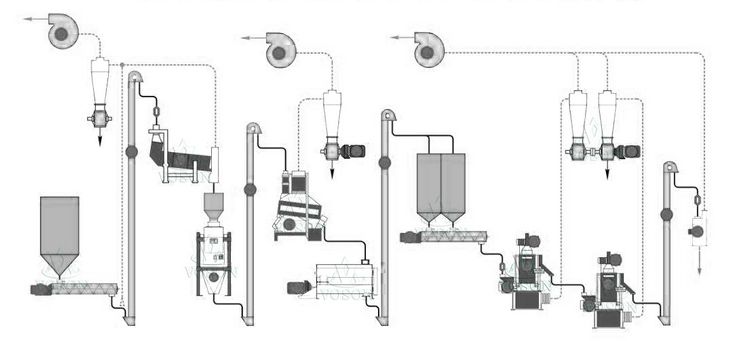

Maize milling or corn meal grinding is processing maize / corn into flour products to make it safe for consumption. The preprocess before milling generally includes cleaning the maize to get rid of dust and other particles, conditioning with a damper, to make it easier to get a high quality flour. For example, there is a processing steps that designed for another client:

→ Cleaning and Conditioning

Remove the materials and particles, that do not make a part of the maize kernels, is crucial as it helps in improving the eminence of the final product. The foreign materials that are got rid of in this process include dust particles, husks, straw, sand, etc.

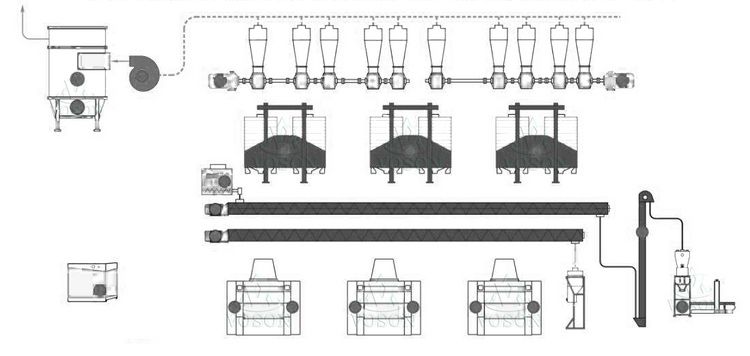

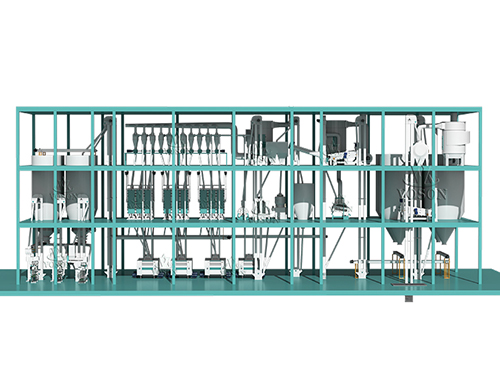

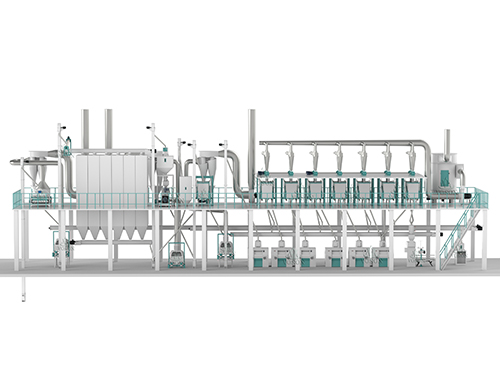

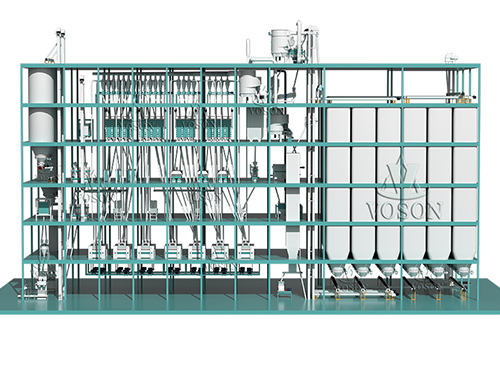

Our engineer have drawn process flow diagrams for the client, and customers, which can make customers more clear about his production line. Every customer deserves our best service. Get a Quote and Details

→ Maize / Corn Flour Milling

After cleaning, the next is about how to grind corn into cornmeal. There are 3 roller millers and 3 double bin sifter, 1 bran machine, powder collector, and automatic packing machine.

Finally, there is a dust collector to ensure a good working environment.