Pneumatic Conveying System

What is Pneumatic Conveying System

Pneumatic conveying technology can perfectly achieve the automatic reception, automatic batching, and supply of raw materials, effectively solving the production problems of food processing enterprises.

Business scope of pneumatic conveying systems

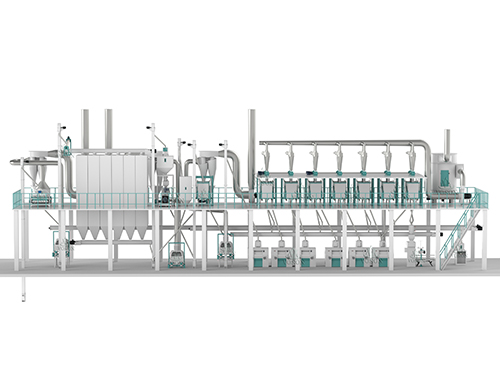

1、AUTOMATIC MIXING AND BATCHING SYSTEM

2、PNEUMATIC CONVEYING AND RELEVANT BULK

3、SOLIDS HANDLING EQUIPMENT

4、OTHER AUXILIARY EQUIPMENT AND ACCESSORIES

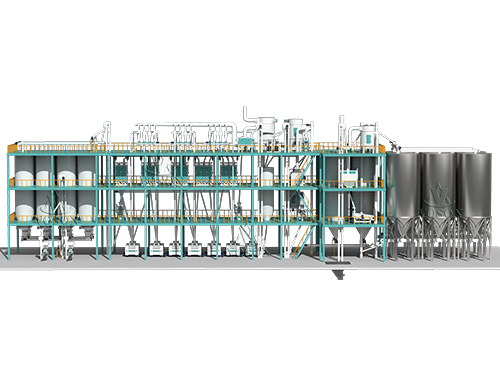

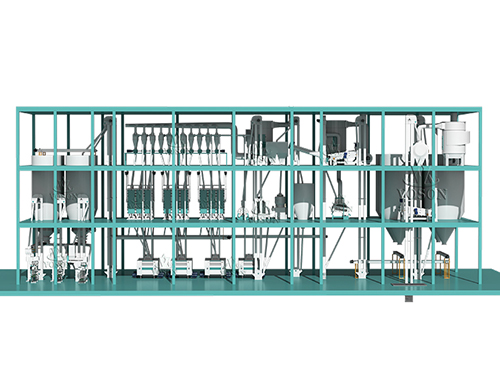

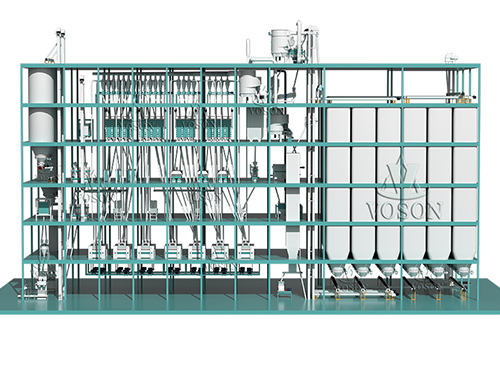

5、WHOLE PLANT PLANING

6、PROCESS AUTOMATION AND CONTROL SYSTEMS

7、POWDER、LIQUID STORAGE SYSTEM

8、SMALL MATERIAL BATCHING SYSTEM

Feature of Pneumatic Conveying System

1、Electrical automation

A dedicated team handles automated programming throughout the entire installation process, allowing you to view and execute different recipes, print production reports, and prepare maintenance plans.

2、Manufacturing and pre assembly

Our pre assembly workshop can provide further quality control assurance. Before delivery, all equipment is assembled, thoroughly tested, and inspected in the workshop. Significantly reduce on-site installation time, improve internal quality control of production, and enable flexible customization to meet special needs.

3、Installation and training

The high-quality installation team (including mechanical engineers, Electrical engineer, supervisors, etc.) strictly abides by the company's installation and operation procedures, and completes the on-site installation and commissioning tasks quickly and efficiently. Conduct comprehensive testing on the system under different states of empty machine and material, and deliver it to Party A for use after fully meeting the standards. Train Party A's control personnel to achieve optimal operational efficiency.

4、Quality and Safety

We have ISO9001 quality certification, and all equipment meets national certification standards. We implement strict quality control over the production process.

Feel confused about that ? You can directly Contact Us for The Price !