Laboratory Flour Mill

In any modern flour milling project, getting things right from the start is more than just a smart idea — it's essential. Whether you're planning a large-scale wheat flour plant or a specialized corn milling line, one of the most overlooked, yet critical steps is pre-production testing. That's where the Laboratory Flour Mill comes in.

At Voson, we not only supply large, complete milling systems — we also offer the compact, powerful laboratory flour mill setups that help our clients move confidently from idea to implementation. In this article, we’ll walk you through what a laboratory flour mill really is, why it matters, and how we design these systems to meet real project demands.

What Is a Laboratory Flour Mill?

Let’s start with the basics. A Laboratory Flour Mill is a small-scale milling system designed specifically for trial production, milling parameter adjustment, and raw grain evaluation. Unlike quality-testing lab equipment (like moisture meters or gluten analyzers), this mill actually simulates the production process — just on a smaller, controlled scale.

Think of it as your test kitchen before opening a full-size bakery.

In a typical setup, a laboratory mill includes compact versions of the key processing steps: cleaning, grinding, sifting, and flour classification. It’s not meant to handle commercial volumes. Instead, it’s designed to give you something even more valuable: accurate data that you can use to fine-tune your plant design.

Why Bother With a Test Mill?

You might wonder — if you already know what kind of flour you want to produce, why take the extra step of milling small samples?Get a Free Quote Now

Here's why our clients consistently thank us for recommending it:

1. Validate Your Raw Grain

Every crop is different — even from the same region. Before committing to a processing line, the laboratory mill lets you understand your raw wheat or corn's properties: hardness, moisture, ash content, and flour yield potential.

2. Simulate Your Final Product

Want a high-gluten bread flour? Or a low-ash, fine-particle cake flour? The lab mill lets you adjust grind settings, screen sizes, and moisture conditions to see what works best for your goals.

3. Minimize Investment Risks

Testing before building prevents costly surprises. We've seen clients avoid major redesigns simply because a laboratory trial exposed a misalignment between their expectations and the raw material behavior.

4. Build Trust with Investors and Partners

For project bids or funding applications, data from a trial mill shows your stakeholders that you're serious — and backed by real-world tests.

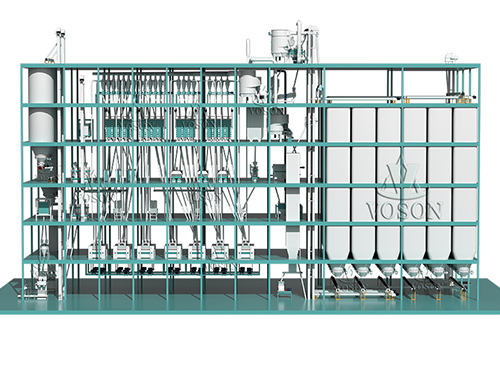

How We Build Laboratory Flour Mills at Voson

At Voson, we’ve built our reputation on full-scale milling solutions — but our laboratory mills follow the same principles: precision engineering, user-friendly operation, and real-world performance.

Let’s walk through how we typically design a lab milling setup.

Step 1: Understand the Application

It always starts with your goal. Are you planning a new wheat flour plant? Or validating the feasibility of corn grits production in a new region? We ask the right questions, like:

- What kind of raw material are you using?

- What type of final product are you aiming for?

- Are you using the lab mill for internal R&D, customer samples, or third-party certification?

Step 2: Select the Right Configuration

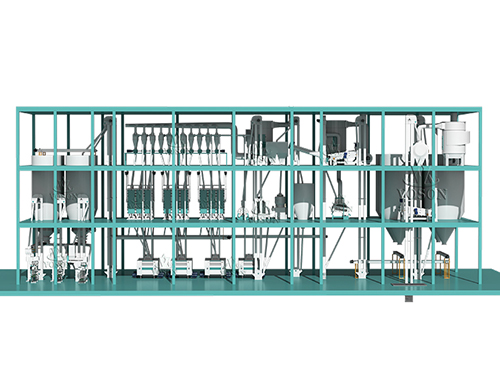

Our standard lab milling setups usually include:

- Miniature Cleaning Equipment – to replicate pre-milling grain handling

- Roller Mill Units – with adjustable roll gaps for break and reduction grinding

- Plansifter or Compact Sifting Systems – simulating flour extraction and grading

- Aspiration & Dust Control – often integrated to match real factory settings

- Data Collection Panels – optional, for clients needing trial data logging

We can also integrate moisture conditioning modules, especially for wheat flour projects where tempering affects milling quality.

Step 3: Assemble and Calibrate

Once configured, our lab mills are fully assembled and tested before shipment. Our engineers ensure that:

- Grinding accuracy meets expectations

- Flour yield matches projections

- Every component is easy to operate and maintain

For clients needing third-party validation, we provide sample test runs with detailed reports.

A Glimpse into the Testing Workflow

In practice, using a laboratory flour mill is a highly flexible process. Here’s what it typically looks like:

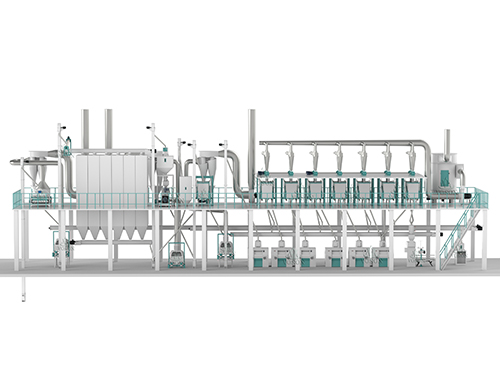

- Receive Raw Grain Sample

A small batch (typically 5–20 kg) of wheat or corn is prepared. - Grain Cleaning & Moisture Adjustment

The sample is cleaned, and moisture may be adjusted to match target specs. - Grinding & Sifting

The sample goes through break rolls and reduction rolls. The flour is sifted, classified, and weighed. - Yield & Quality Analysis

Results are compared across settings to evaluate flour yield, ash content, particle size, and color. - Parameter Fine-Tuning

Roll gaps, screen mesh, and feed rates are adjusted to simulate different production scenarios.

Real-World Use Cases

Although this article is based on typical scenarios rather than a specific client project, here are some real-world applications where our lab flour mills have made a clear difference:

- African Clients Testing New Wheat Imports

One client ran side-by-side milling tests for different wheat batches before finalizing supplier contracts. - Southeast Asia – Developing Instant Cornmeal

A regional food startup used our lab mill to simulate degerminated corn flour production, helping them reduce losses in the later full-scale project. - University Research Projects

We’ve also supplied lab-scale flour mills to academic institutions studying regional grain processing methods.

Where Laboratory Milling Meets Industrial Engineering

What sets Voson apart isn’t just our ability to build compact trial systems. It’s that we back them with a deep understanding of complete milling solutions.

If your lab results tell you something needs adjusting — your required flour extraction ratio, your grinding fineness, your moisture profile — we can help you translate those findings directly into production line configurations.

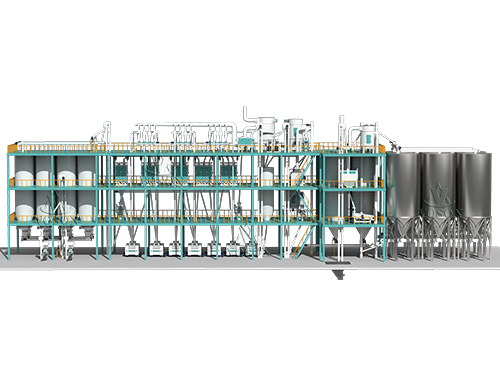

And when it’s time to scale up, our team is ready with turnkey capabilities in:

- Complete Wheat Milling Systems

- Corn Grits and Corn Flour Production Lines

- Custom Engineering for Regional Grains

From testing to design, manufacturing, installation, and commissioning — we cover it all.

Whether you're planning a full production plant or just want to explore how your raw grains perform in practice, our laboratory flour mill solutions are here to help you make smart decisions early.

Want to learn more about our wheat milling equipment, corn milling lines, or how we bridge the gap from lab data to factory operations? Let’s connect — our engineers are always ready to turn your raw material into a successful milling project.Get a Free Quote Now