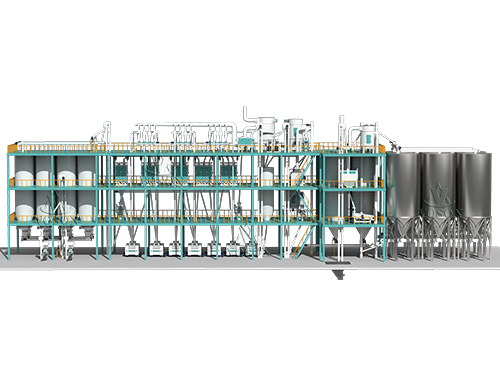

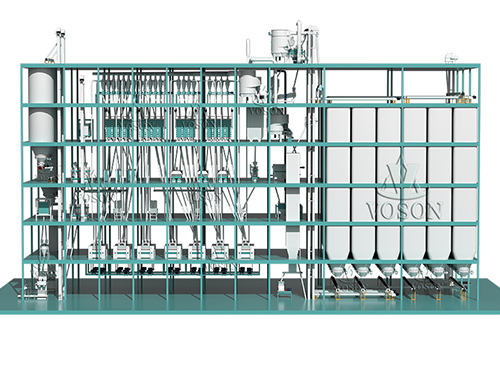

Integrated Flour Mill and Grain Storage Solutions

As a leader in the grain processing and flour production equipment sector, VOSON is at the forefront of providing efficient, sustainable, and integrated flour mills and grain storage technologies worldwide. By combining cutting-edge technology with modern management practices, VOSON is changing the game for the industry, improving both production efficiency and food safety and quality.

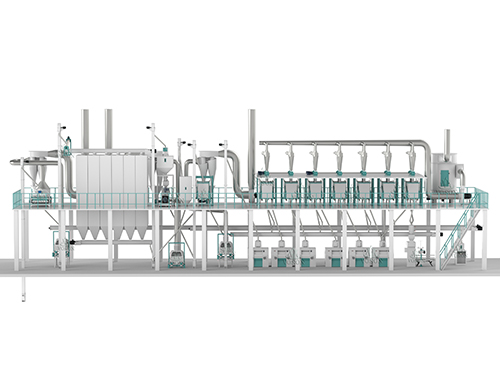

Grain Storage: Securing Quality and Sustainability

VOSON offers advanced grain storage equipment for large flour mills and grain processing plants around the world, ensuring long-term storage and efficient material handling. With intelligent control systems, VOSON can monitor and manage storage conditions in real-time, preventing spoilage, moisture, and pest infestations, thus maintaining the quality of the raw materials.

Key Storage Solutions:

Silos: Large, vertical structures used for bulk grain storage, ideal for maintaining moisture control and minimizing contamination.

Hermetic Storage: Airtight bags that prevent moisture and pest infiltration, extending the shelf life of grains.

Smart Storage Systems: Equipped with sensors to monitor temperature, humidity, and gas levels, these systems optimize storage conditions in real-time.

Sustainability in Grain Storage:

Modern facilities are increasingly adopting eco-friendly methods such as solar panels on roofs and wind turbines to power grain storage operations. These measures help reduce the environmental footprint of grain storage and milling. Get a Free Customize

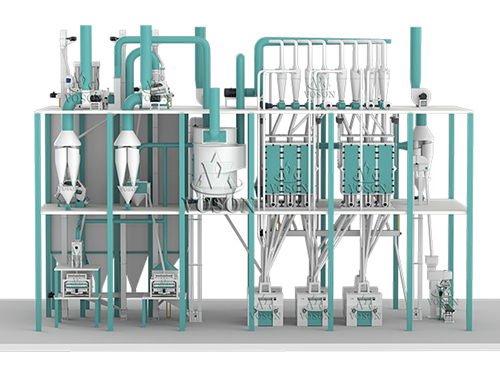

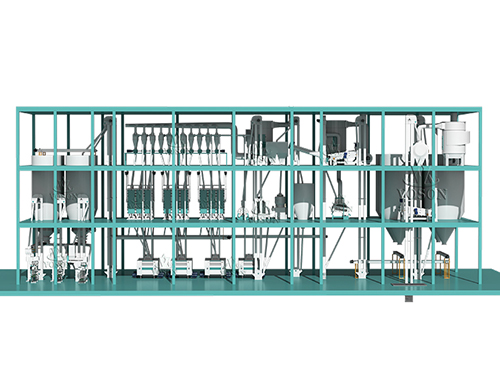

The Flour Milling Process: From Raw Grain to Finished Product

VOSON flour milling equipment incorporates the latest automation technologies, enabling precise control over every step of the milling process to ensure high-quality flour and optimal production efficiency. Each piece of milling equipment is rigorously tested to ensure long-term reliability and stability.

Key Milling Technologies:

Roller Mills: These are used to break down the grain into smaller pieces and separate the flour from the bran and germ.

Sifters: Separate different particle sizes to ensure the right consistency and texture of the flour.

Blending Systems: Ensure the proper mixture of different types of flour, additives, or other ingredients.

Automation in Milling:

Modern mills are equipped with automated systems that ensure smooth and efficient production. Conveyor belts, automated feed systems, and real-time quality control help streamline the milling process.Get a Free Customize

Integrating Grain Storage and Flour Milling: The Key to Efficiencyility

VOSON’s integrated solutions combine grain storage and flour milling, reducing transportation time and energy consumption. With smart control systems, grain flows directly from storage to milling, ensuring a stable supply of raw materials and high production efficiency.

Benefits of Integration:

Reduced Transport Costs: With grain storage located near the milling area, transportation time and costs are minimized.

Continuous Supply: Automated systems ensure that grains are transferred directly from silos to mills without interruption.

Improved Operational Efficiency: The entire process, from storage to milling, is monitored and controlled by a central system, ensuring maximum productivity.

Case Study: Automated Grain Storage and Milling in Action

In modern facilities, automated grain handling systems play a crucial role. Robotic arms move grain from silos to the milling section, while digital monitoring systems track moisture levels, temperature, and grain quality throughout the process.

The Future of Flour Milling and Grain Storage

VOSON continues to lead the way in providing integrated flour milling and grain storage solutions that not only ensure food quality but also enhance production efficiency and sustainability. As technologies advance, VOSON is committed to driving the green, intelligent, and efficient future of the global grain processing industry.