How to Extend the Lifespan of Milling Machinery

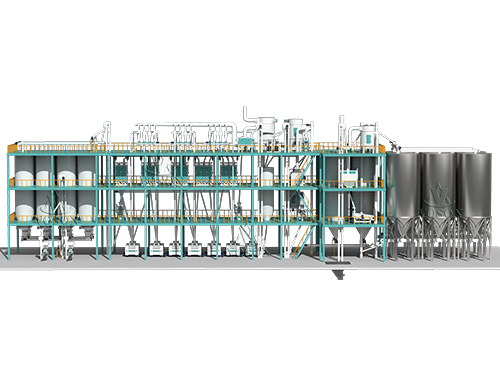

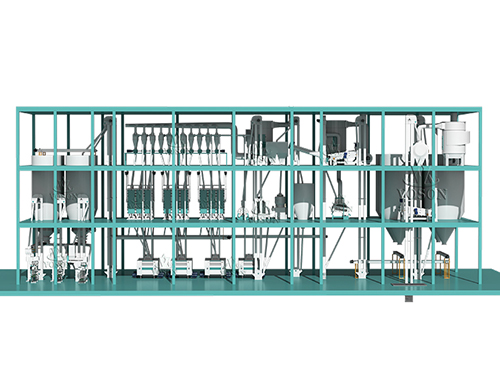

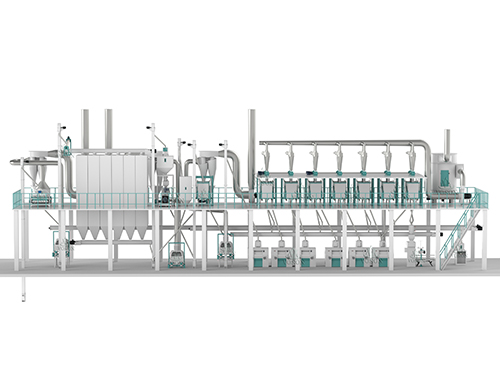

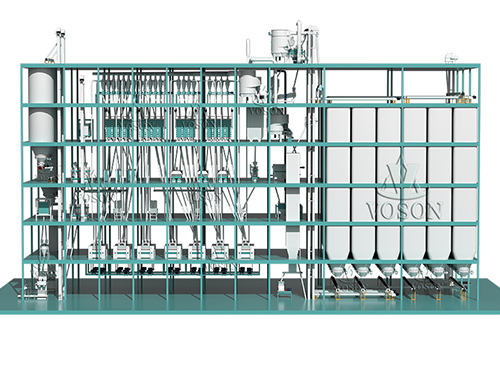

At Voson Grain Engineering Machinery, we understand that the lifespan of milling machinery is crucial for sustaining milling efficiency and reducing downtime. With our industry expertise, we’ve gathered some best practices to help you extend the lifespan of Milling Machinery,maximize equipment value, enhance productivity, and ensure consistent results over the long term.

1、Regular Cleaning and Maintenance

Voson recommends daily cleaning and regular checks to prevent buildup and contamination, which can impact both milling efficiency and equipment longevity. Voson milling equipment is designed with accessibility in mind, making it easier for operators to perform routine cleaning and inspections.

2、Lubrication Maintenance

Proper lubrication, following Voson's recommended schedules, is essential to reduce friction on grinding rollers, bearings, and gears. We provide comprehensive lubrication guides with our machinery to ensure parts stay in optimal condition, reducing the risk of unexpected downtime and costly repairs.

3、Monitor and Adjust Machinery Parameters

For our clients, Voson provides tailored parameter adjustment advice to keep machines running efficiently. By monitoring and optimizing roller gaps, airflow, and screen quality, Voson equipment maintains high milling consistency and performance.

4、Professional Operator Training

Voson offers in-depth training for operators to ensure they understand best practices for equipment handling, routine maintenance, and industrial machinery care. This training is designed to help clients extend the lifespan of milling machinery while maintaining consistent milling quality.

5、Quality Raw Material Control

Voson’s equipment comes with high-quality de-stoners and magnetic separators, enabling clients to efficiently remove impurities from raw materials. This step is essential in protecting machinery from excessive wear and tear and improving grinding quality.

6、Electrical System Checks

Our equipment is engineered with durability in mind, but regular electrical checks are still crucial for preventing malfunctions. Voson also advises clients to ensure a stable power supply to avoid disruptions and safeguard machinery.

7、Advanced Cooling and Dust Control

Voson machinery includes integrated cooling systems and effective dust control designs, which help to extend machine life even in challenging environments. These features are crucial for maintaining equipment stability and optimal milling efficiency.

8、Use of Voson Certified Parts

Using high-quality, certified parts ensures equipment stability and consistent milling quality. Voson provides original spare parts designed to fit our machinery precisely, helping clients avoid downtime and keep equipment running at its best.

By following these maintenance tips from Voson, you can maximize the lifespan and performance of your milling machinery. Our commitment to excellence and client success is reflected in every piece of equipment we produce, helping you achieve reliable, efficient milling operations.

We can offer many types of Complete Maize/ Wheat flour production line. We provide quotation, design, installation and after-sales. There are 30t maize flour milling machine, 30-50T Wheat Flour Machine, 50-150t maize processing plant, 100-300T Wheat Flour Mill Plant and 500t maize milling plant if you are interested in our product! Get a Free Quote Now