How Much Does It Cost to Start a Flour Milling Business?

As the global grain processing industry expands, many investors are considering entering the flour milling sector. But how much does it really cost to set up a flour mill? What is the flour machine cost? What are the key factors influencing the investment?

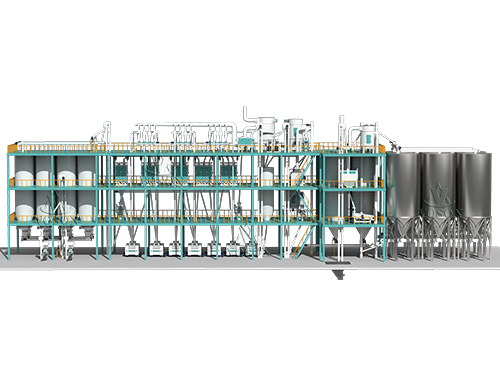

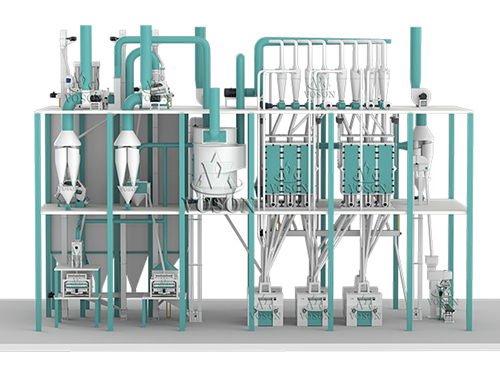

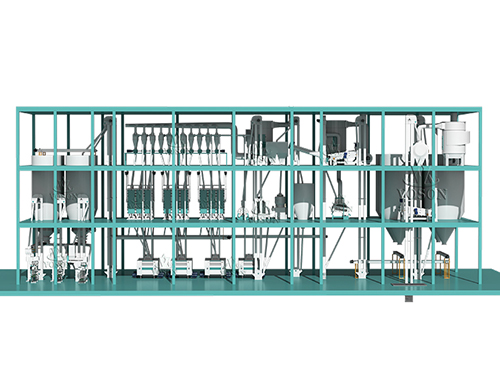

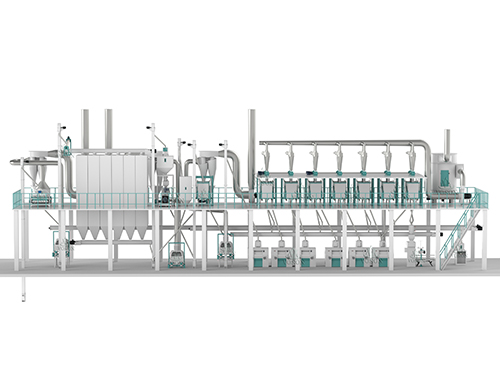

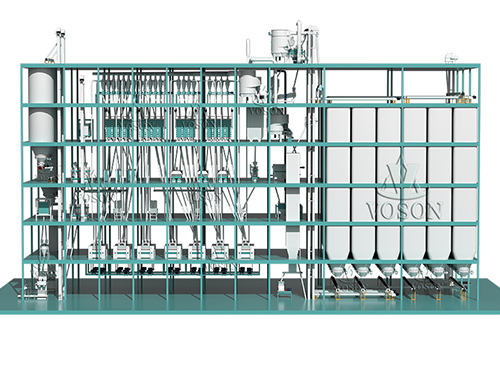

Henan Voson Grain Engineering Machinery Co., Ltd. (Voson), a leading manufacturer of grain processing equipment and engineering solutions provider, offers a detailed cost breakdown and expert guidance to help you make an informed decision.

Key Factors That Affect Flour Mill Setup Cost

1、Factory Construction & Infrastructure Costs

The cost of building a flour mill depends on land prices, construction materials, and labor costs.

Small-scale mills (5-20 tons/day): Require a few hundred square meters of space.

Medium to large mills (30-100+ tons/day): May need thousands of square meters.

Choosing the right location with stable grain supply and market demand is essential for long-term profitability.Get a Free Customize

2、Flour Milling Equipment Investment

The type and capacity of equipment directly impact your investment:

Small-scale (5-20 tons/day): $50,000 – $200,000

Medium-scale (30-100 tons/day): $200,000 – $800,000

Large-scale (100+ tons/day): $800,000 – $3,000,000

Voson offers a full range of flour milling equipment, including cleaning, grinding, sifting, and packaging solutions designed for efficiency and durability.

3、Installation, Commissioning, and Maintenance

Proper installation is key to smooth production. Voson provides:

On-site installation guidance

Equipment commissioning & staff training

Ongoing technical support

4、Operational Costs & Profitability

Labor, electricity, and maintenance contribute to operational expenses.

Automation can lower labor costs and improve efficiency.

Return on Investment (ROI): Most flour mills recover costs within 2-5 years due to steady flour demand.

How to Reduce Flour Mill Investment Costs?

Reducing the initial investment in a flour mill requires a strategic approach that balances cost savings with long-term efficiency. Here are some key strategies to optimize your budget while maintaining high production standards:

1、Invest in energy-efficient equipment to lower electricity consumption, reducing operational costs in the long run without compromising output quality.

2、Opt for semi-automated production lines instead of fully automated systems, which can significantly cut down initial investment while still improving efficiency compared to manual operations.

3、Select durable and high-quality equipment from a trusted manufacturer like Voson to minimize frequent breakdowns, reduce maintenance costs, and extend the lifespan of machinery.

4、Optimize factory layout and workflow design to enhance space utilization, reduce material handling time, and improve overall productivity, ultimately lowering hidden costs associated with inefficiencies.

5、Work with an experienced engineering partner who provides turnkey solutions, like Voson, ensuring professional factory design, equipment selection, and installation, which helps avoid costly setup mistakes and ensures a faster return on investment.

By carefully considering these factors, investors can build a cost-effective and high-performing flour mill that maximizes profitability while keeping initial expenses under control.

Voson’s Turnkey Solutions for Flour Mill Investors

Voson provides complete turnkey solutions, including:

✅ Custom factory design & layout planning

✅ High-quality, energy-efficient milling equipment

✅ Full installation, commissioning, and training

✅ Ongoing after-sales support

We have successfully delivered flour milling projects in Africa, Asia, and South America, helping businesses maximize profitability.Get a Free Customize