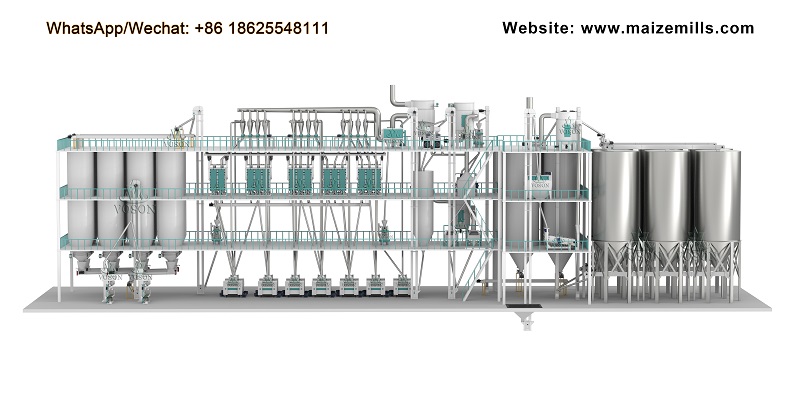

500T Industrial Maize Milling Plant

- Capacity: 500 tons per day

- Production: Graded maize grits and graded flour

Maize milling plant or corn flour milling plant adopts dry method and excellent automation solution for maize flour milling.

Maize milling plant or corn flour milling plant adopts dry method and excellent automation solution for maize flour milling.

Maize milling plant or corn flour milling plant adopts dry method and excellent automation solution, and furthest reduces manual cost and production cost. The professional corn processing project designers and commissioning engineers team ensures the technological advancement, which not only reduces energy consumption, but also reduces the impurities, dust and bran speck impact to end products.

It’s perfect for the entrepreneur planning to enter the maize meal market with a milling capacity of up to 500 tons of maize per day. Simply provide a building, water and an electrical supply and you are set to go. We provide turnkey projects service.

The Maize Milling Plant ensures an extraction rate of between 70% and 75%* (Super/Grade 1), well above the industry norm of 65% - 70% (Super/Grade 1).

Customized machine and solutions for your maize milling business means suitable and reasonable and maximized your profitability.

We are experts in maize processing industry for years. Our production processes make maize grits and all kinds of maize flour, which can produce good beer and spirits, and maize meal for tortillas, arepas, instant maize meal, corn snacks and other maize based products. And also offer comprehensive milling solutions for the diverse corn varieties and end products around the globe.

1. Raw grain cleaning section: one screening, one stone removing, one magnetic separation. Equipped with winnowing system, it can remove the big and small impurities.

2. Peeling and degerming section: it adopts the process of twice peeling, once polishing, twice screening and once fine section.

3. Corn grits section: it adopts the technology of fine grits making, flour brushing, screening classifying and suspending.

4. Flour milling section: it adopts the technology of several times of grinding and screening.

Grinding: the material enters into the grinder and is ground into fine flour.

Screening: it separates the fine powder from the material.

5. Measuring and packaging section: the warehouse can reduce amount of labor. The measuring package can adopt manual method or electrical method.

End products: maize grits, maize flour and maize bran

Maize flour fineness:40-200 meshes (the flour fineness is adjustable)

Appearance and taste: even granularity, golden color, smooth kernels, fine powder, pure and natural taste.

Purchase a suitable small maize flour mill machinery for your business is halfway on the success. With the 100t/d maize flour milling machine, you can start your business in a warehouse or a small yard, just with limited invest. Get a Free Quote Now

1. A Leading Maize Mill Manufacturer in China.

2. Whole plant layout design.

3. Field installation, commissioning and free training.

4. Supply free quick-wear parts with machine when delivery.

5. Lifelong Service: Video technical support, Online support, Spare parts, Field maintenance and repair service.

If you have any needs about our products and service, please contact us by one of the following ways to get quotation and service !

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one day. Please feel free to contact us!