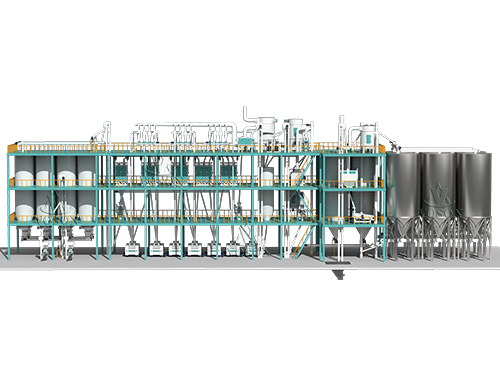

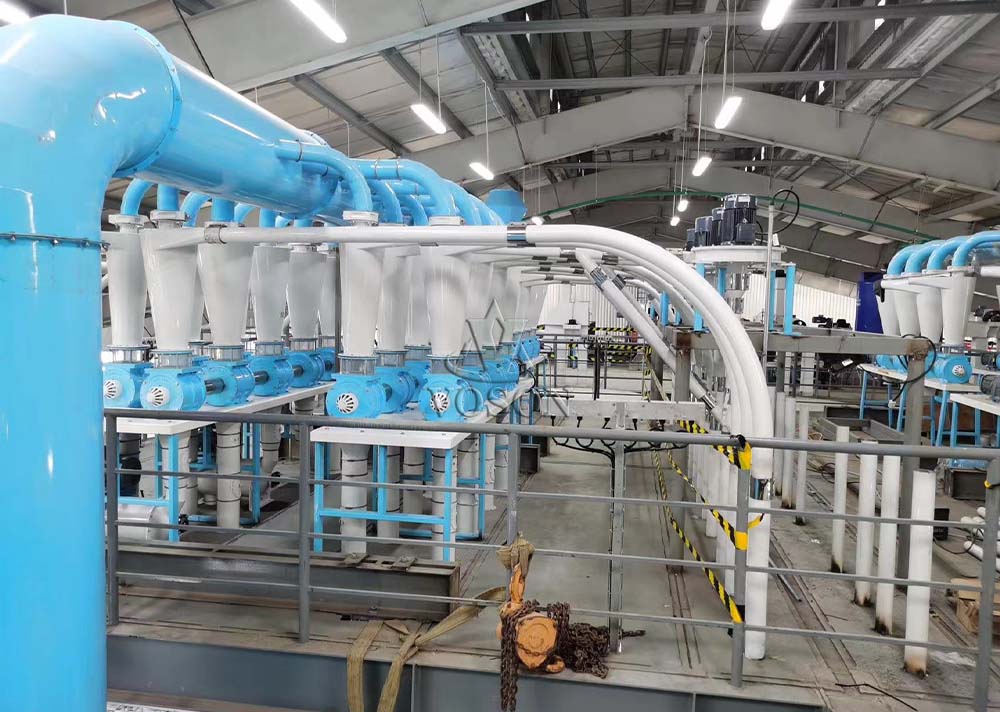

150t wheat flour mill assembled steel frame platform

150 tons steel structure wheat flour mill equipment is designed for large-scale production environments to support and install equipment.

The assembled steel frame platform of the 150-ton flour processing equipment structural design of the platform is based on equipment load, operation requirements and safety considerations. It adopts a modular assembly method, which not only improves installation efficiency, but also facilitates future maintenance and expansion.

Design Requirements Analysis

1、 Load Requirements

The platform for 150-ton equipment must provide sufficient load-bearing capacity to support the static weight of the equipment, dynamic loads during operation, and additional weight from personnel and materials. The structural design must ensure both overall stability and localized strength.

2、 Operational and Maintenance Needs

Frequent operation and maintenance of flour processing equipment require the platform to offer adequate space for personnel movement and access. Additionally, the platform design must facilitate quick equipment installation and removal, minimizing downtime during repairs or maintenance.

3、 Safety Requirements

The design must comply with national building codes and safety standards, incorporating measures for earthquake resistance, slip prevention, and fall protection. Safety railings should be installed around equipment, with escape routes and safety signage clearly marked.

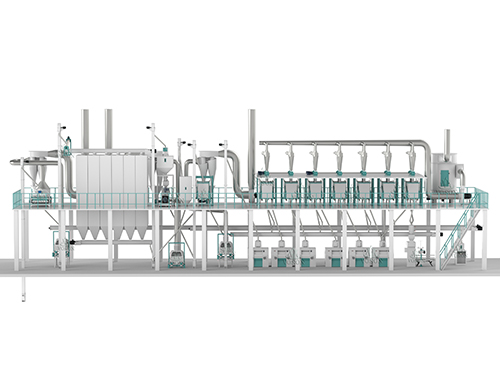

Flow chart of 150 tons steel structure Wheat flour Mill Line

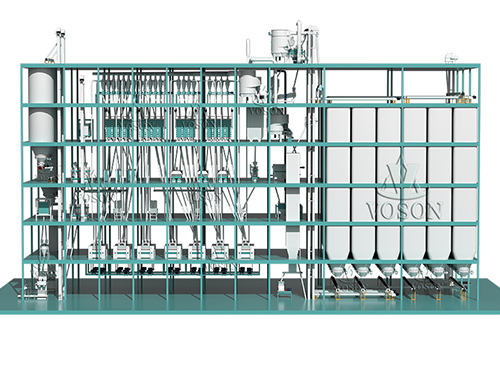

1、 Load Capacity Design

Based on the weight of the 150-ton equipment, the platform supports must be constructed from high-strength steel, such as Q235B or Q345B. Finite element analysis (FEA) is used to simulate load conditions and verify the overall stability and local strength of the platform under static and dynamic loads. The structural design follows the specifications outlined in the “Code for Design of Steel Structures” (GB 50017-2017).

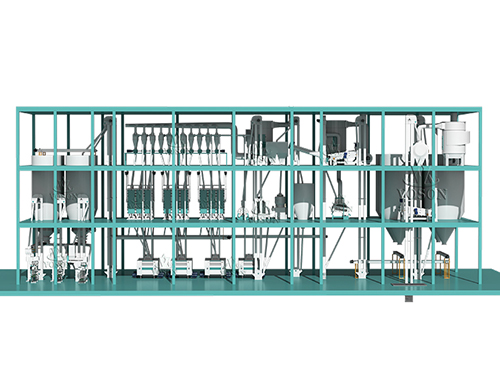

2、 Modular Structure Design

The modular design of the steel frame platform aims to simplify the construction process and enhance future maintenance flexibility. Each module consists of steel beams, columns, and support systems. These modules are pre-fabricated off-site and assembled on-site, reducing construction time and on-site welding. This approach shortens the project timeline and enhances installation safety.

3、 Layout Optimization

The platform layout must consider equipment positioning, operational requirements, and process flow. Adequate space should be provided around the equipment for operation and maintenance, with access pathways, inspection platforms, and inter-floor stairways or lifts for easy personnel and material movement. The platform surface should be treated with anti-slip coatings for worker safety.

VOSON offer many types of Complete Maize/ Wheat flour production line. We provide quotation, design, installation and after-sales. There are 30t maize flour milling machine, 30-50T Wheat Flour Machine, 50-150t maize processing plant, 100-300T Wheat Flour Mill Plant and 500t maize milling plant if you are interested in our product! Get a Free Quote Now